Hard machining

Task

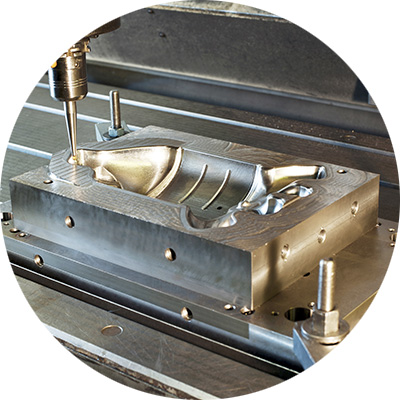

Injection mould – plastics processing

Die made of 1.2342 (48 HRc)

9 mm deep M6-6H blind hole thread for fastening standards.

Solution

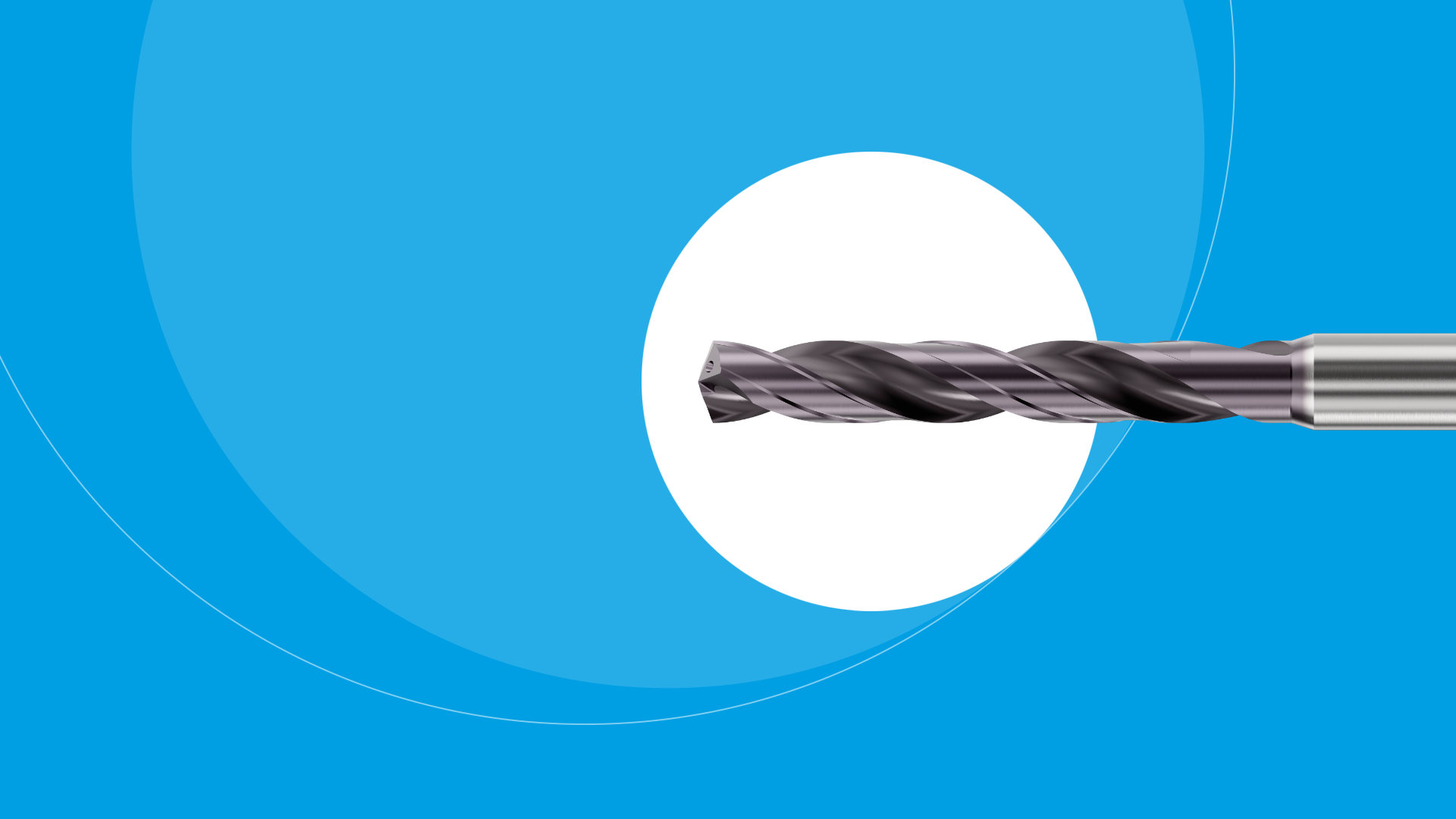

NORIS TWIN HT

- For hardened steels and hard castings up to 55 HRc

- Suitable for through and blind hole threads

- Thread depth up to 1.5 x D

- Available chamfer length form C

Special HSSE-PM substrate allows economical hard machining at final hardness up to 55 HRc!

NORIS WE + NORIS UNI

The quick-change inserts of the WE series are intended for use in our quick-change holders of the UNI and UNI/HP series. The five sizes are divided into corresponding thread dimension ranges and are available in different versions. For most quick-change inserts, the tool is adapted via a quick-change ball clamping system, whereby a separate insert is required for each shank diameter. The quick-change inserts are suitable for producing right-hand and left-hand threads.

The quick-change holders of the UNI series are primarily intended for use on CNC machining centres, CNC lathes and conventional machine tools.

Optimized chip removal by cooling along the tool shank.

Customer benefit

- Process reliability

- Robust

- Economical

-

Tool details

- Machine taps NORIS TWIN

- Tapping chuck NORIS UNI

-

REIME NORIS also has the right solution for your task

- Get in touch with us – we will be happy to advise you!

Task

Forming tool – Punching tool

Stamp from 1.2842 (62 HRc)

18 mm deep M10-6H blind hole thread

Solution

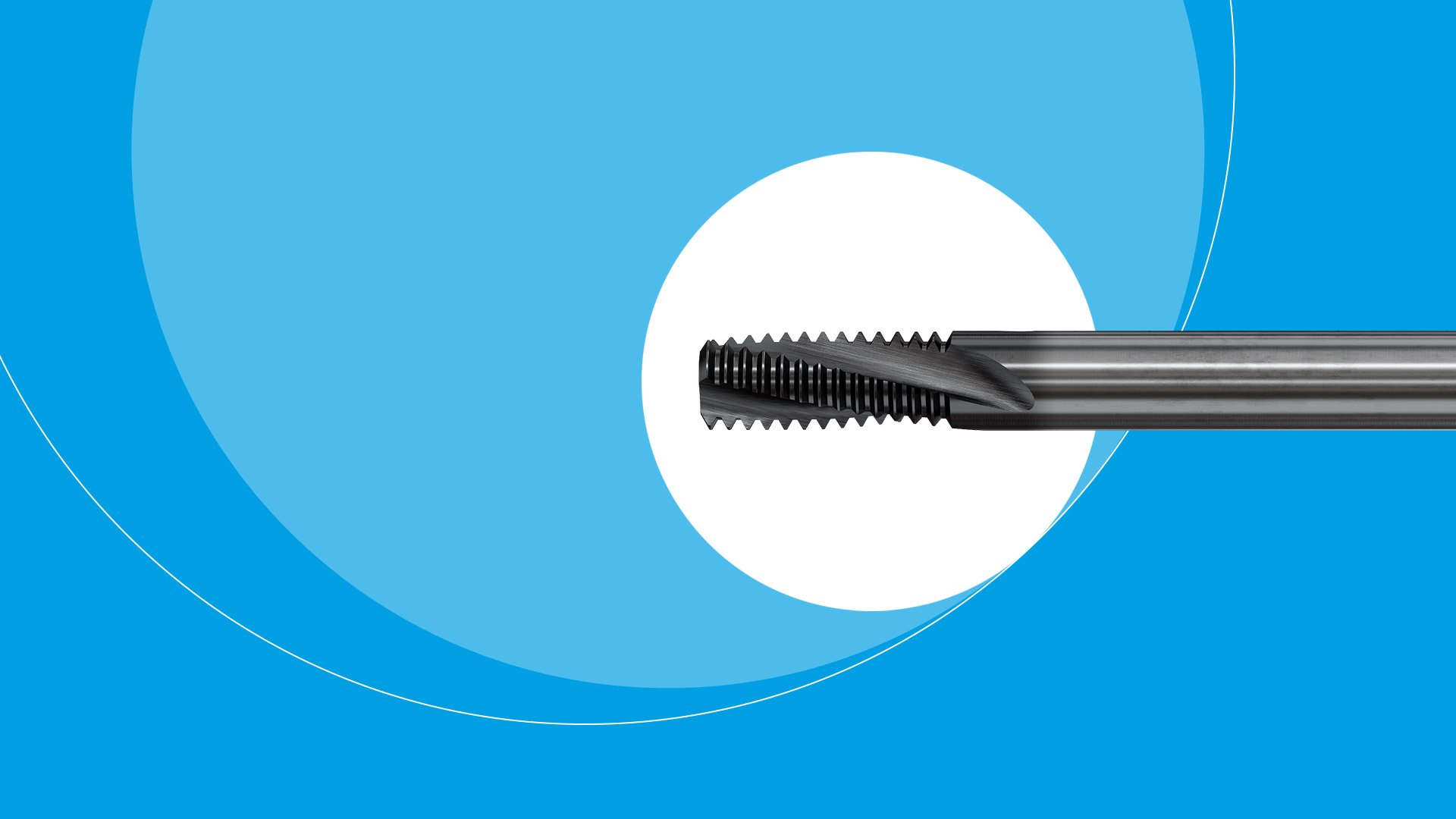

NORIS ZTF HT

For hard to machine and hard materials from 44 HRc to 66 HRc. These left-rotating thread milling cutters enable the production of threads without pre-drilling the core hole.

Thread directly into the full material, without pre-drilling!

Customer benefit

- Fast

- Process reliability

- Zero scrap

-

Tool details

- Thread milling cutter NORIS ZTF HT

-

REIME NORIS also has the right solution for your task

- Get in touch with us – we will be happy to advise you!