Thread mills

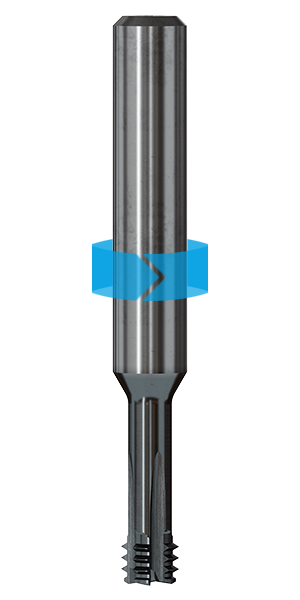

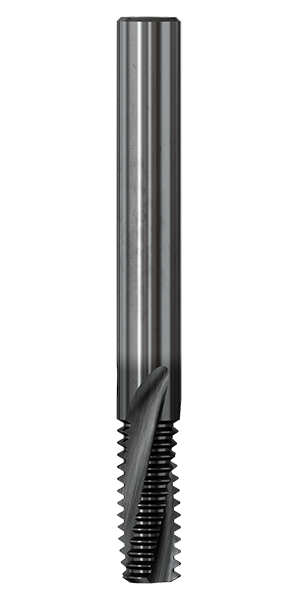

NORIS ZTF HT

Circular diving thread milling cutters for hard to cut and hard materials of 44 HRc to 66 HRc

This left rotating thread mills enable the production of threads without pre-drilling the core hole.

-

Are you looking for the right thread mill for your individual requirements?

- Shop now in our online store!

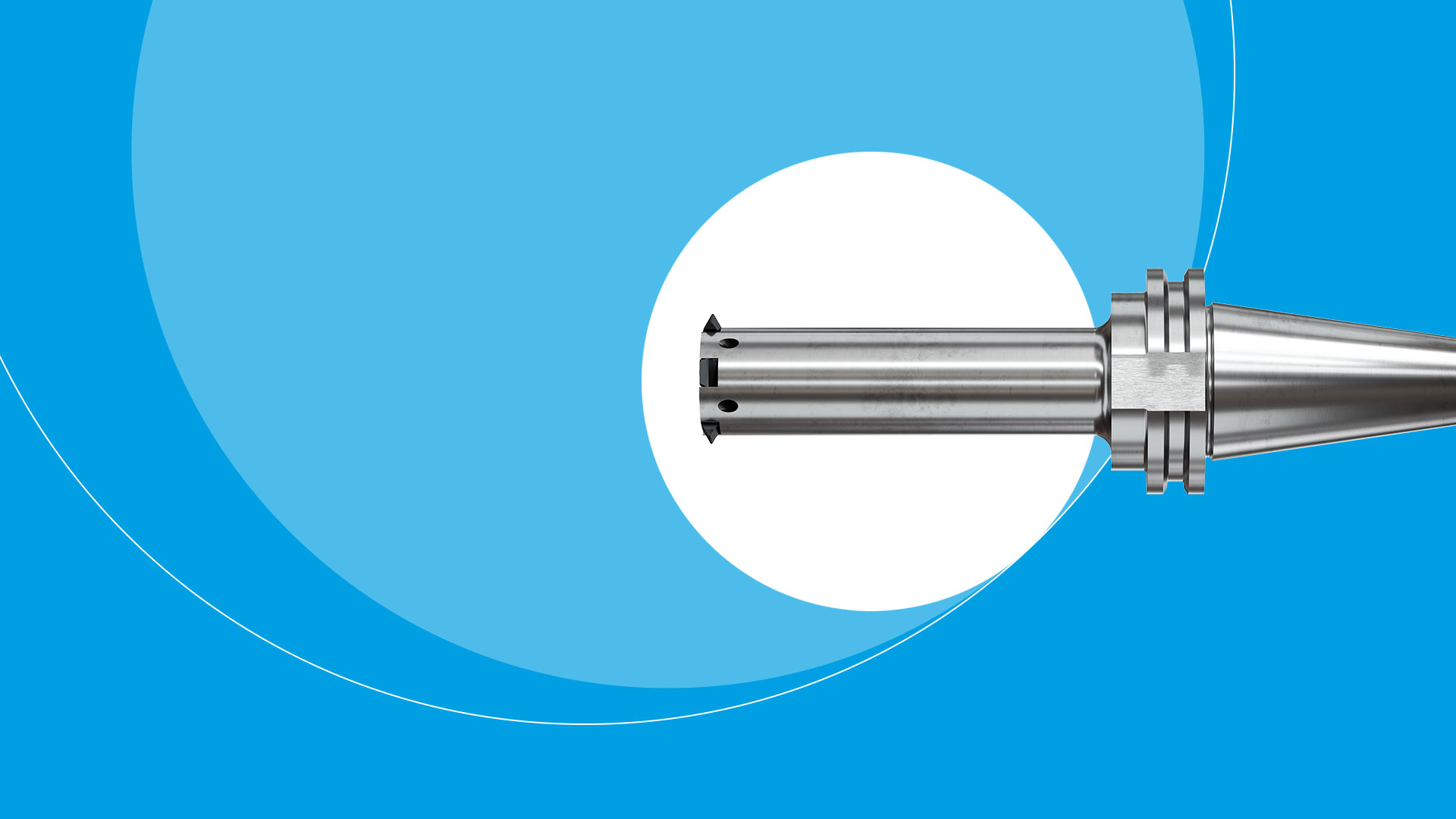

NORIS SF

Just one tool for countersink and thread.

-

Are you looking for the right thread mill for your individual requirements?

- Shop now in our online store!

NORIS EIR HR

For the production of small threads

-

Are you looking for the right thread mill for your individual requirements?

- Shop now in our online store!

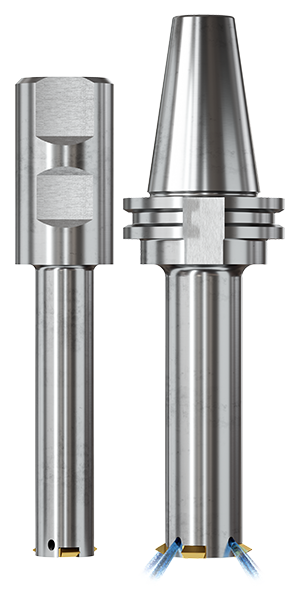

NORIS NES

For the production of large threads

-

Are you looking for the right thread mill for your individual requirements?

- Shop now in our online store!

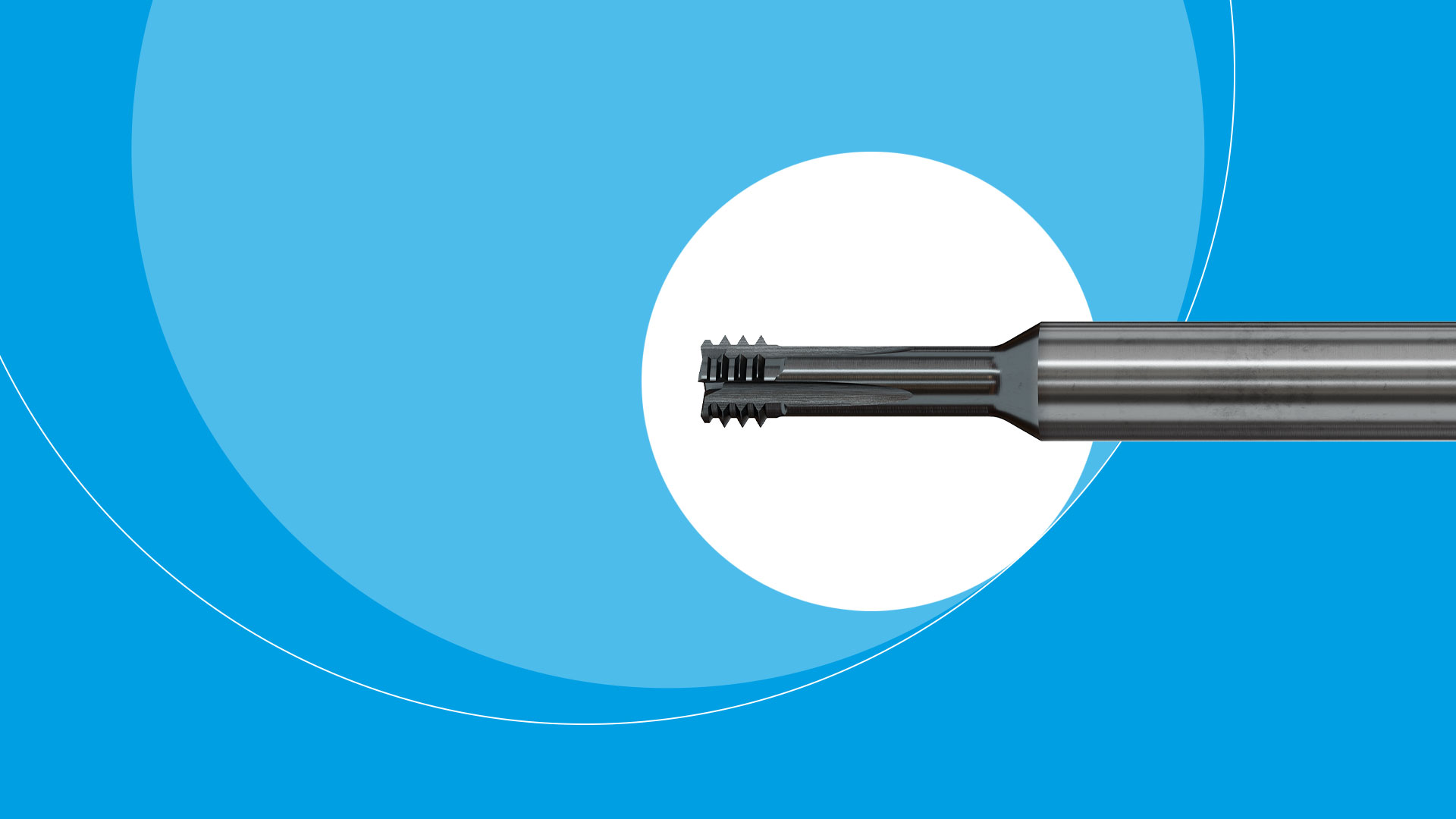

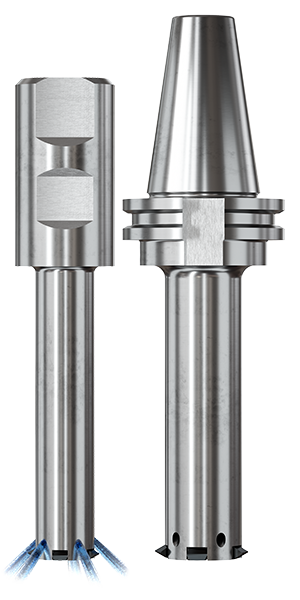

NORIS NES TS

For the production of large threads

Shorter machining times through tighter tooth spacing. This will lead to a more economic thread production.

-

Are you looking for the right thread mill for your individual requirements?

- Shop now in our online store!