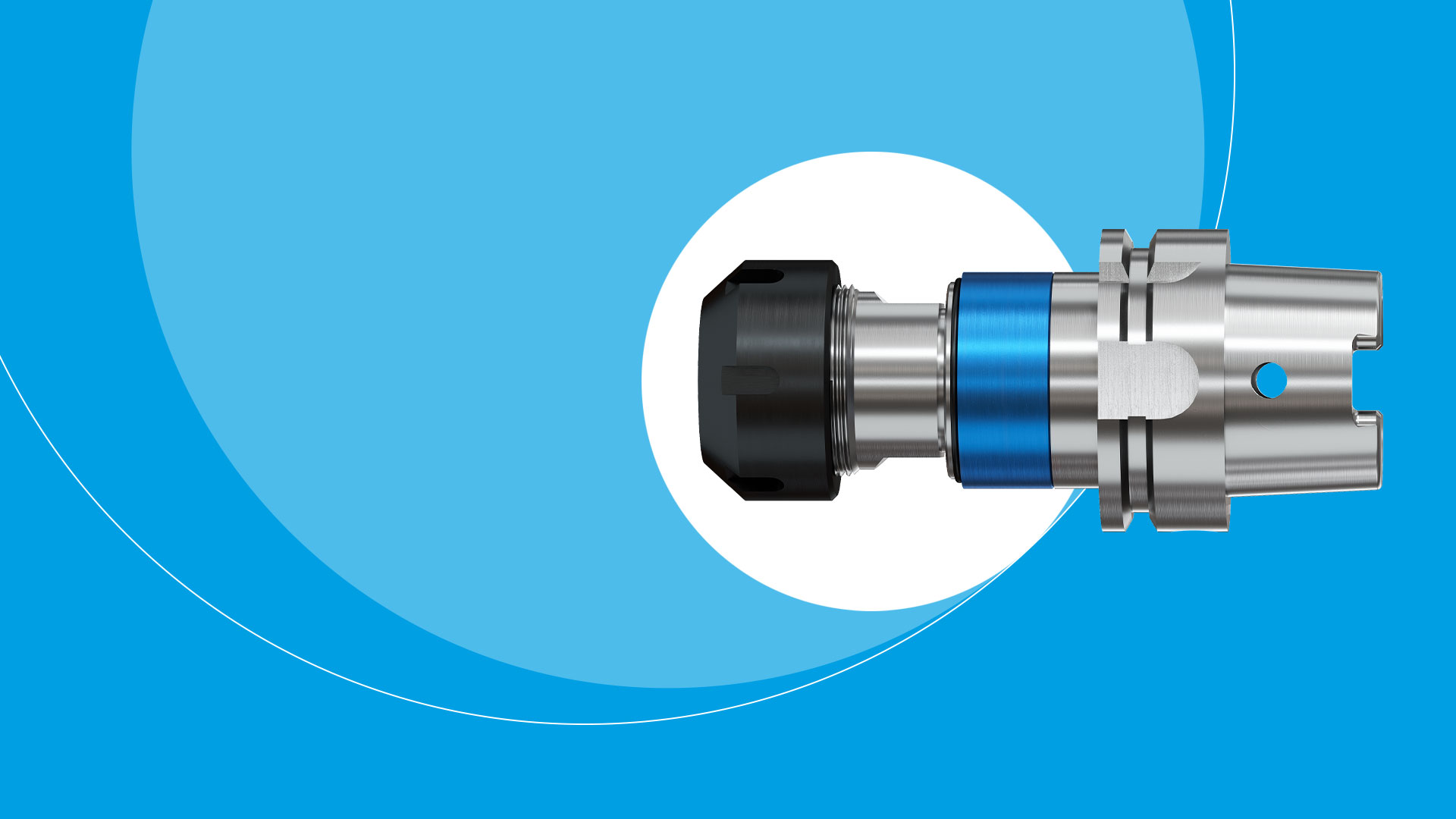

Tap holder

HelixPro

For use on machines with synchronous spindle

- serve as absorbing link between synchronous spindle and tap / cold-forming tap, and compensate pitch differences between threading tool and synchronous spindle

- provide the high concentricity of a rigid tool holder

- guarantee safe clamping of taps / cold-forming taps by collets with square drive

- do not necessitate tools with special shanks

- guarantee process safety in the synchronous production of threads

- Shank type DIN 1835 B+E available

-

Are you looking for the right tap holder for your individual requirements?

- Shop now in our online store!

UNI

For use on CNC machining centres and other machine tools

Application range

The quick-change tap holders of the UNI series are made primarily for use on CNC machining centres, CNC turning lathes and conventional machine tools.

Type UNI

for conventional thread production without internal coolant-lubricant supply, marked with a yellow ring on the gripping sleeve.

- Shank type DIN 1835 B+E and DIN 69893 A available

Clamping of threading tools by:

- quick-change adapters type WE

-

Are you looking for the right tap holder for your individual requirements?

- Shop now in our online store!

UNI/HP

For use on CNC machining centres and other machine tools

Application range

The quick-change tap holders of the UNI/HP series are made primarily for use on CNC machining centres, CNC turning lathes and conventional machine tools.

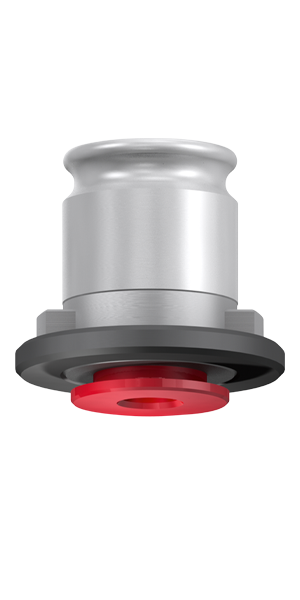

Type UNI/HP

for thread production with internal coolant-lubricant supply up to 50 bar (700 psi), marked with a red ring on the gripping sleeve.

- Shank type DIN 69893 A available

Clamping of threading tools by:

- quick-change adapters type WE

-

Are you looking for the right tap holder for your individual requirements?

- Shop now in our online store!

UNI/HP/ER

For use on CNC machining centres and other machine tools

Application range

The collet holders of the UNI/HP/ER series are made primarily for use on CNC machining centres, CNC turning lathes and conventional machine tools

Type UNI/HP/ER

for thread production with internal coolant-lubricant supply up to 50 bar (700 psi), marked with a red ring on the gripping sleeve.

- Shank type DIN 69893 A available

Clamping of threading tools by:

- collets type ER-GB

-

Are you looking for the right tap holder for your individual requirements?

- Shop now in our online store!

ISP

For the production of large threads

The quick-change tap holders of this series are made especially for the production of large threads. In addition, it is possible to perform a drilling or countersinking operation without changing the holder, by simply blocking the length compensation by means of a locking screw.

- With modular shank to DIN 69871 A, DIN 2080 and DIN 228 B available

The resulting advantages are as follows:

- minimum coaxial deviation between drilled hole and thread

- no time-consuming exchange of holders, with reduced costs

Tool clamping is done by means of quick-change adapters of our IE series.

-

Are you looking for the right tap holder for your individual requirements?

- Shop now in our online store!

Quick-change adapters and accessories

Tool adaptation by means of quick-change adapters

The quick-change adapters of our WE series have been designed for use in the quick-change tap holders of our UNI and UNI/HP series. The five sizes have been divided into corresponding thread size ranges, and are available in different types. The adaptation of the tool is made by means of a quick-change ball clamping system in most quick-change adapters, with a separate adapter being necessary for each shank diameter. Our quick-change adapters are suitable for the production of right-hand and left-hand taps.

-

Are you looking for the right tap holder for your individual requirements?

- Shop now in our online store!