NORIS TWIN GGV HM TICN

New carbide tap NORIS TWIN GGV HM increases reliability and durability

NORIS TWIN GGV HM

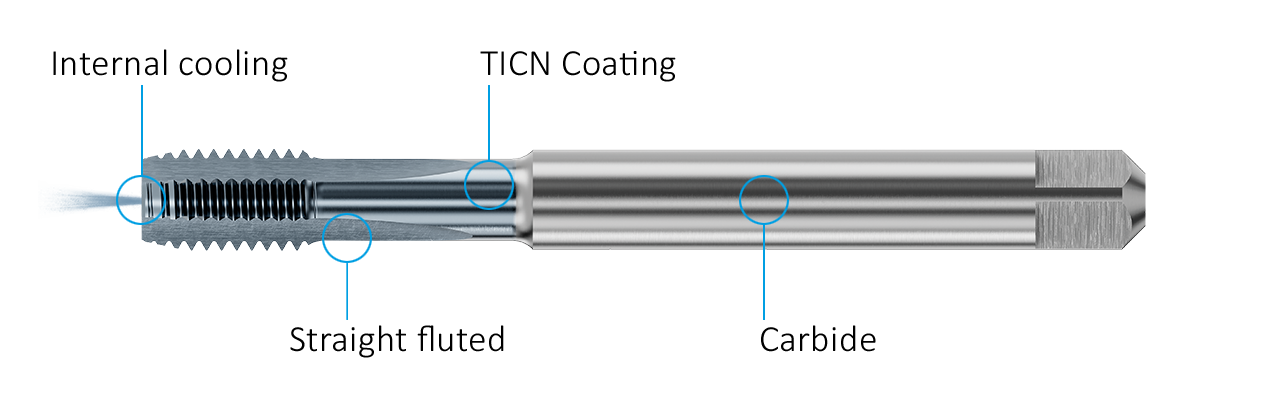

- Solid carbide cutting material, more flutes and optimized geometry for more tool life in abrasive cast iron materials

- Increased tolerance for more tool life in abrasive or clamping workpiece materials

- TICN coating for less wear and longer tool life

Application

- P

- M

- K

- cast iron

- 10 – 80

- Emulsion/Dry

- N

- S

- H

Available dimensions

- M

- MF

- UNC

- UNF

- G

- NPT

- M4

–

M16

ISO2X - M12x1,5

–

M20x1,5

ISO2X -

–

-

–

-

–

-

–

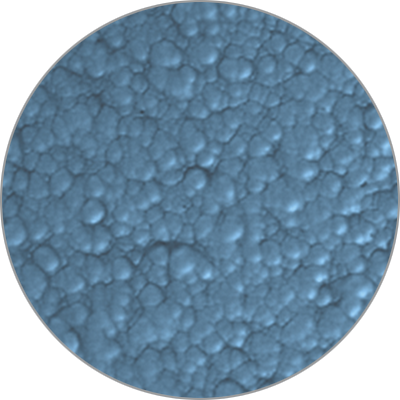

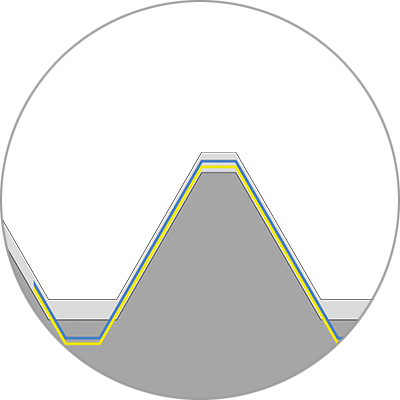

- TICN

A high hardness of more than 3000 HV and low friction values protect against abrasive wear

Coating

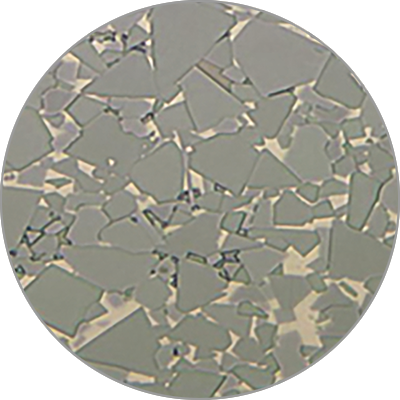

- Carbide

Tough-hard ultrafine grain grade for the processing of extremely hard materials, cast materials, composite materials, plastics and graphite - Coolant bore

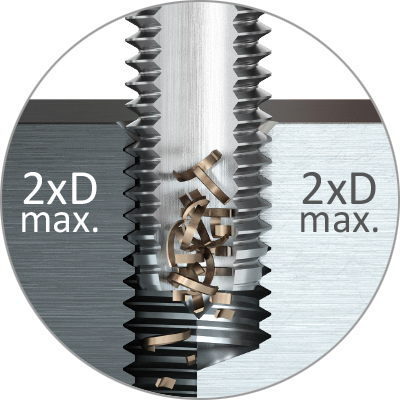

Ensuring cooling lubrication and chip evacuation during machining

Substrate

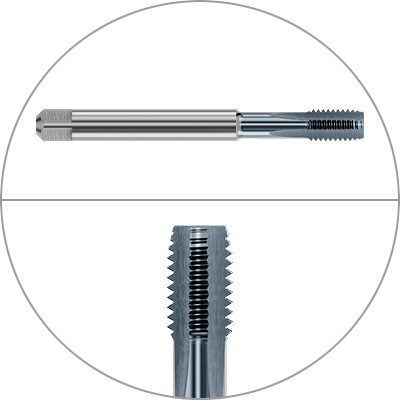

- GGV

Special geometry for modern cast iron (GJL, GJS, GJV) - Straight fluted

Stable cutting geometry achieves the greatest possible resistance to mechanical stress - Higher number of flutes

Geometry

- X-Tolerance

The larger production dimension guarantees longer use, especially in abrasive and clamping materials

Thread portion

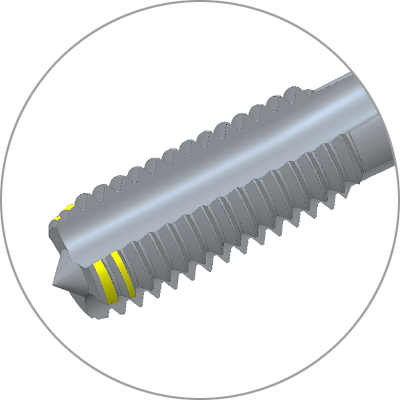

- Form E

- Short gate length for low thread runout

Chamfer length

Product-Highlights

Tool features

- Special designed geometry for cast materials

- Reduced chamfer length for short thread run out

- High quality basic material

- With internal coolant

- Higher number of flutes

Advantages

- High cutting speed

- High production stability

- Increased wear resistance

- Reduced cold welding and friction

Customer benefits

- Long machine run = higher productivity

- Increase production safety = reduce machine down time