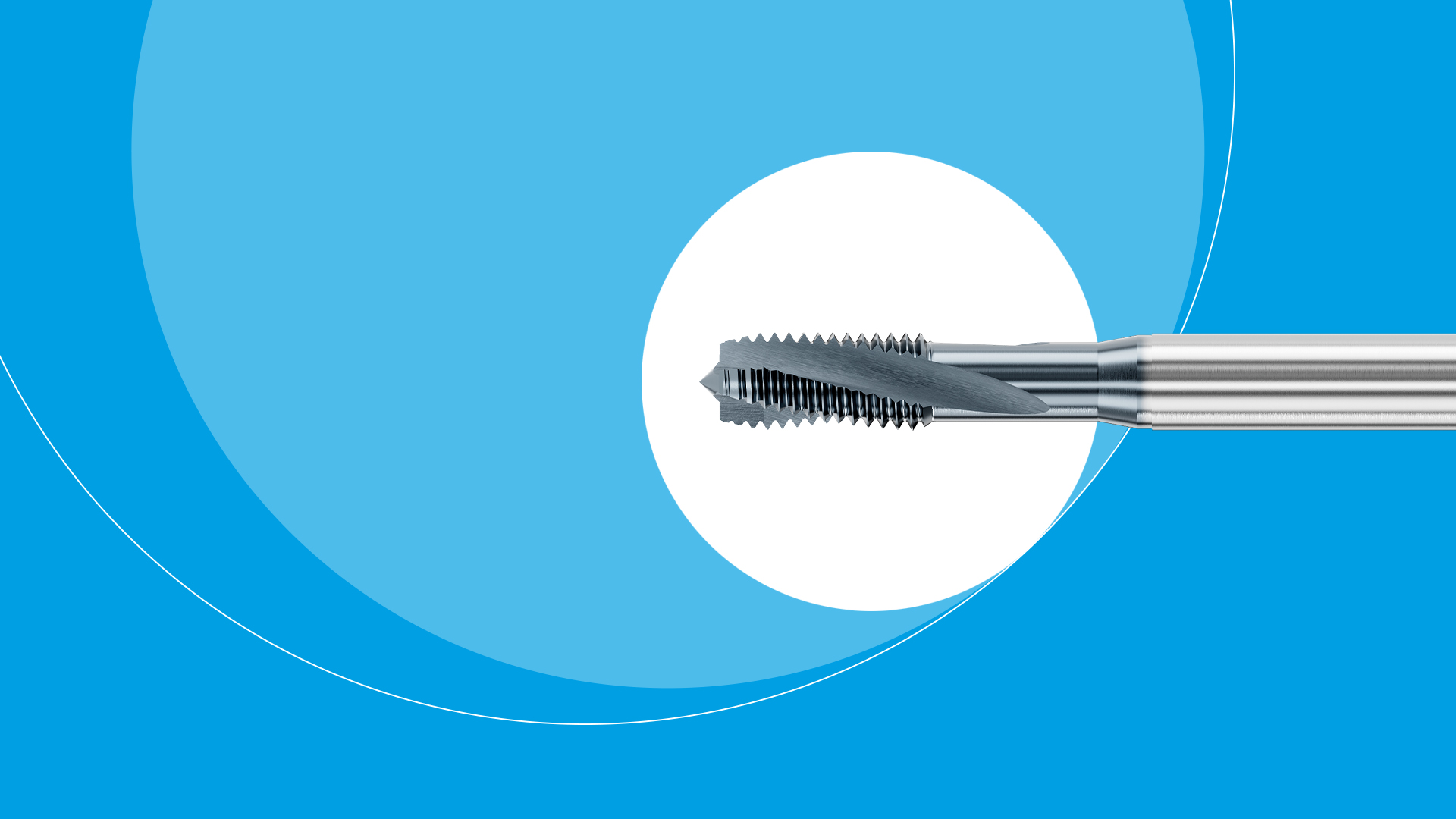

NORIS SL15 TI+

NORIS SL15 TI+ HSSE TICN CS: The new thread specialist for titanium alloys

NORIS SL15 TI+

- Additional spiral point for tighter rolled and smaller broken chips

- Large clearance angle prevents cold welding

- High process reliability and excellent thread quality

Application

- P

- M

- K

- N

- S

- heat res. Ti-all.

- 2 – 4

- Emulsion/Oil

- H

Available dimensions

- M

- MF

- UNC

- UNF

- G

- NPT

- M3

–

M10

ISO2X -

–

-

–

-

–

-

–

-

–

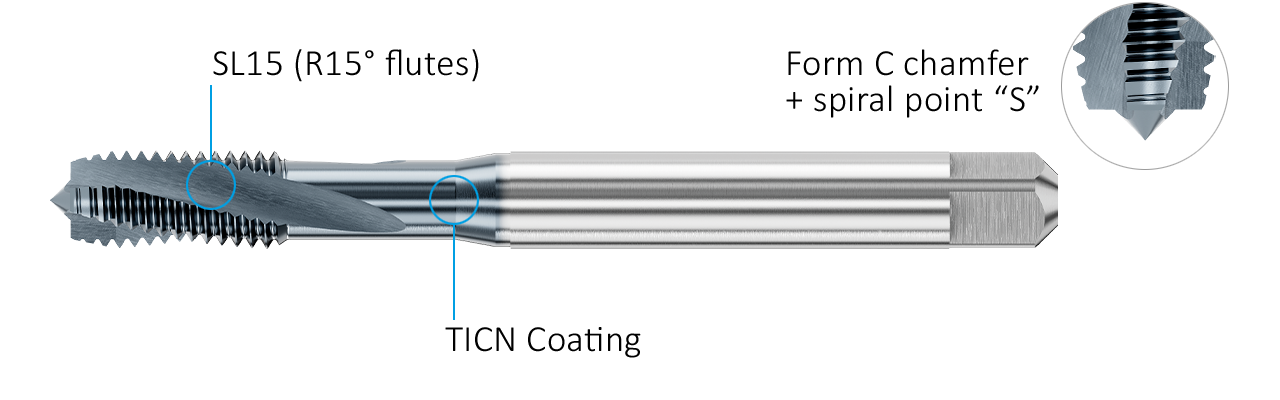

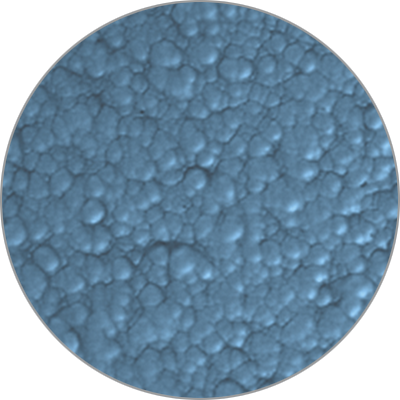

- TICN

A high hardness of more than 3000 HV and low friction values protect against abrasive wear

Coating

- HSSE

The high hardness of HSSE substrate results in exceptional toughness and wear resistance

Substrate

- Ti+

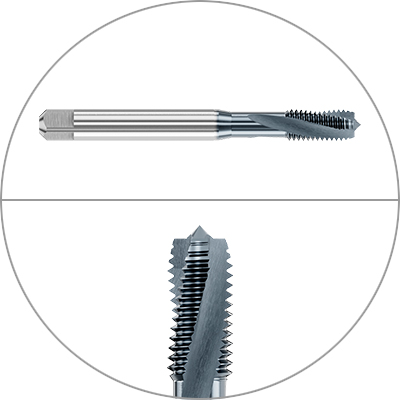

New developed tap geometry Ti+ for process-reliable thread production in selected titanium alloys - SL15 (R15° flutes)

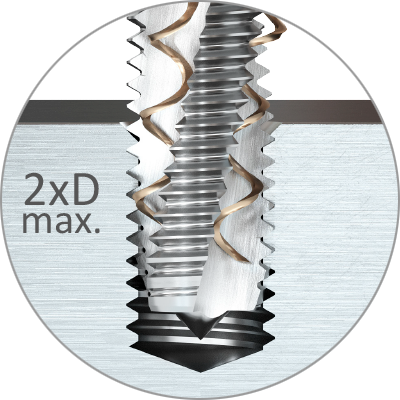

Stable cutting flutes for 2xD thread depth

Geometry

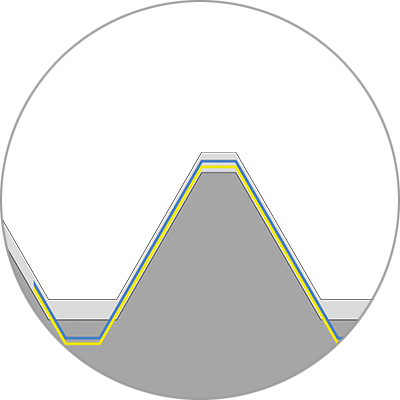

- X-Tolerance

The larger production dimension guarantees longer use, especially in abrasive and clamping materials

Thread portion

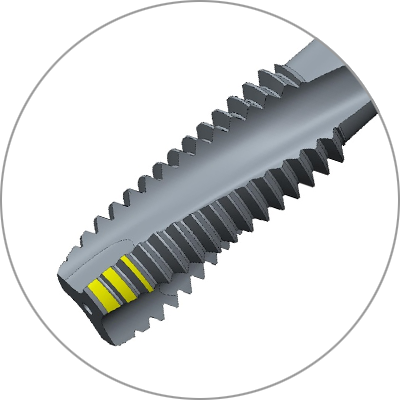

- C chamfer + spiral point “S”

Helix reduction in the chamfer, caused by the spiral point, ensures short broken chips

Chamfer length

Product-Highlights

Tool features

- New developed tap geometry Ti+ for process-reliable thread production in selected titanium alloys

- Helix reduction in the chamfer, caused by the spiral point, ensures short broken chips

- Stable cutting flutes SL15 (R15° flutes) for 2xD thread depth

Advantages

- High tool life

- Reduced problems with chips

- High surface quality

Customer benefits

- Less tool costs = less investment

- Long machine run = higher productivity

- High surface quality = better image